Energy management and energy conservation performance

We established the Delta Energy Online (EnOL) management system to provide real-time energy consumption and load analysis through methods such as energy planning, efficiency, consumption analysis, and equipment management. The EnOL system optimizes equipment operations, enhances power consumption efficiency, and serves as the basis for evaluating energy saving improvements. Delta's energy consumption at global operation sites in 2024 included electricity and fossil fuels (e.g., natural gas, diesel, gasoline, and liquid petroleum) and externally purchased heat. The total energy consumption was 892,407 MWh, with electricity accounting for 92%. The total energy use increased by 10.6% compared to 2023, chiefly due to the expansion of the factory, increase of production lines and output, which has led to increase the use of electricity. Fossil fuels are mainly used to power emergency power generators, lawn mowers, forklifts, company vehicles, as well as boilers in living areas (including dormitories and cafeterias).

-

Saved 55,277 MWh of electricity and reduced carbon by around 37,577 metric tons in 2024

In 2011, Delta established a cross functional energy management committee, and an Energy-Saving Technology Team was further organized within the committee. Over the years, the team regularly audited the energy consumption result to find more opportunities and it has implemented various energy conservation and improvement measures for public facilities. These audits serve as checkpoints, allowing Delta to evaluate its progress in reducing energy consumption. By coordinating firsthand experience with energy conservation from internal and external consultants, the team is able to implement these practices at global operation sites. We started implementing the internal carbon pricing mechanism in 2021 and encouraged global operation sites to apply for investment as well as implement energy-saving and carbon reduction projects (e.g., replacing the water ring vacuum pumps at the Wujiang Plant, introducing magnetic suspension chillers at the Dongguan Plant, replacing old chillers at the Pingjhen Plant, and introducing the high-efficiency chillers at the Thailand Plants. These projects were expanded across production plants to strengthen energy and resource management and applied to innovative low-carbon developments as well as innovative energy conservation and carbon reduction technologies.

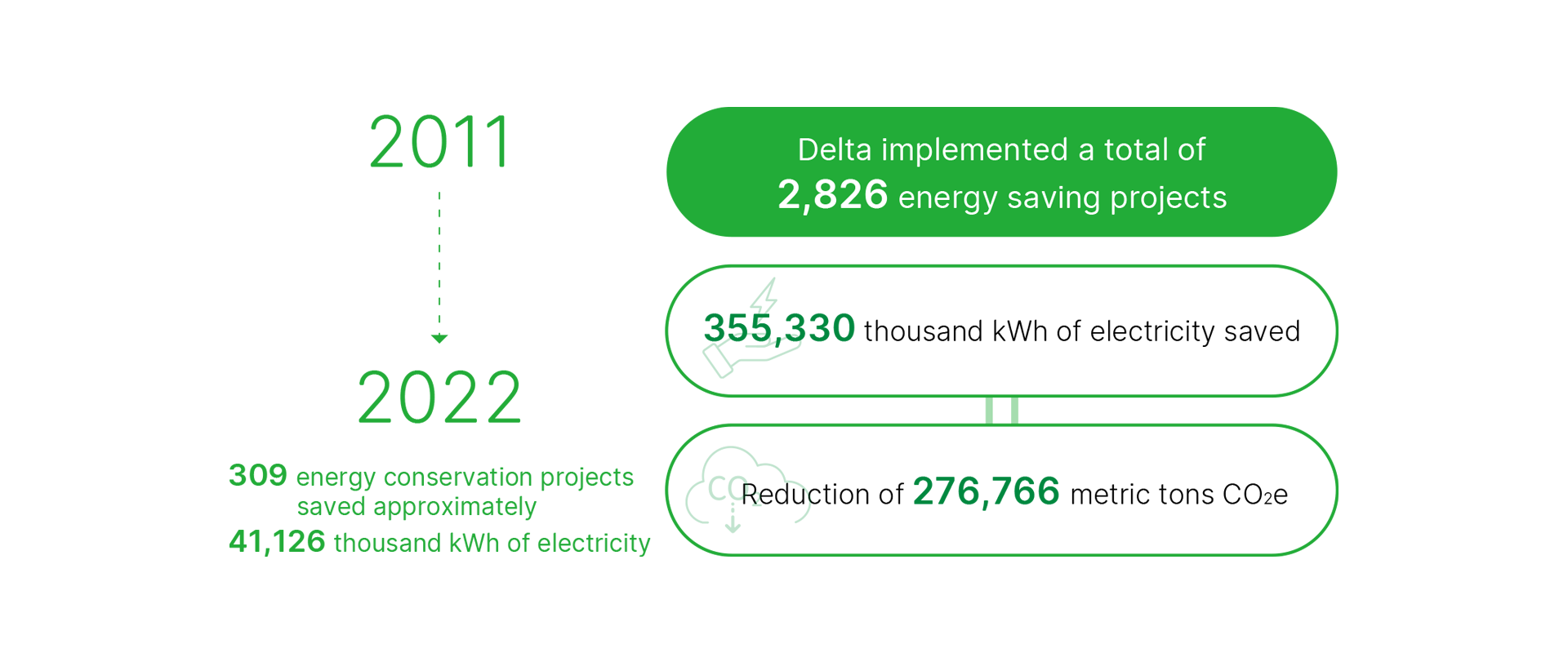

From 2011 to 2024, Delta's global operation sites have continued to implement energy conservation and carbon reduction measures. The Company put 457 energy conservation projects into practice in 2024 and saved approximately 55,277 thousand kWh of electricity, equivalent to approximately 37,577 metric tons CO2e. Delta implemented a total of 3,693 energy conservation projects from 2011 to 2024 with an estimated 459,106 thousand kWh of electricity saved, equivalent to a reduction of 350,640 metric tons CO2e.